Many thanks to Longman Brewery and their head brewer Stephen Perrin for having 7 of the Lewes Home Brew club over on a Saturday for a brew day

HB Porter Recipe

OG: 1.062

PG: 1.016 (proposed final gravity?)

Volume: 100 litres / 20litres (have added the 20litre amounts to help me)

ABV: 6.0%

- C/F Pale: 20Kg / 4Kg (some sort of pale malt - Maris Otter?)

- Crystal: 1.5 / 300g

- Flaked Oats:3Kg / 600g (this is quite stouty - perfect for winter!)

- Chocolate Malt 1.5Kg / 300g

- Brown Malt 1Kg, 200g (like a brown porter)

- Aromatic malt 2Kg / 400g

Liquor Treatment:

- AMS - 33 g/ml

- Calcium Chloride: 19 g/ml

- Calcium Sulphate: 8 g/ml

- Sodium Chloride: 17 g/ml

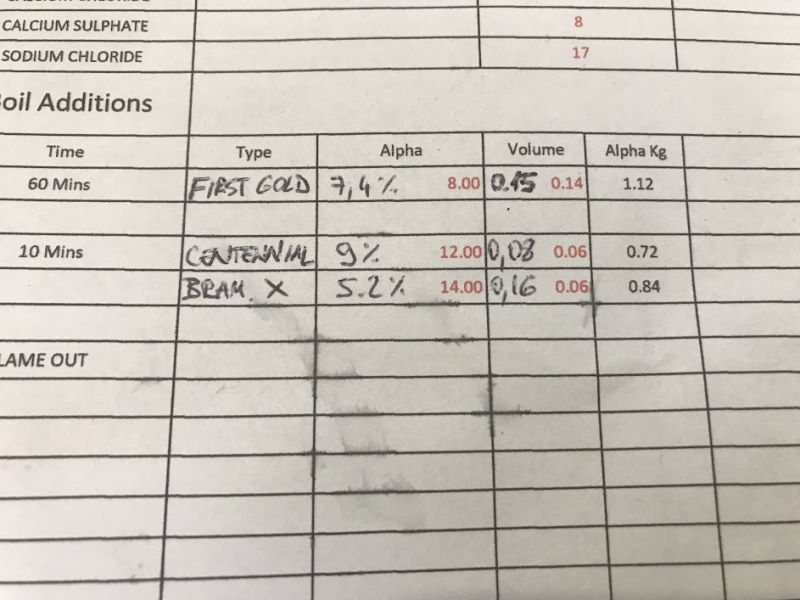

Hop additions

- start 150g First Gold Leaf 7.4% alpha

- 10 min to go 160g Bramling Cross leaf 5.2% alpha 80g Centennial leaf 9% alpha

- flame out 100g amarillo

Stephen squeezing 29Kg of Malt into the Mash Tun. We left out some of the chocolate malt as it wouldn’t fit until during the sparge

3 vessel system. Mash tun to the right, Hot Liquor Tank on top and Boil Kettle to the left.

Plate chiller in the centre. Amazing how fast it can cool 80 litres

https://www.brewersfriend.com/2011/02/13/hot-liquor-tank-for-all-grain-brewing/

- Brewing water is heated in Hot Liquor Tank (HLT) - liquor is treated water

- Mashing happens in Mash Lauter Tun (MLT) - we mashed for 1 hour

- Wort is drained into Boil Kettle (BK) - we boiled for 1 hour

adding the malts - mashing in at 68C

adding the malts - mashing in at 68C

choosing hops

Hop additions

keeping everything sterile. We also used Iso propol alcohol in spray bottles to spray connectors. Apples are not allowed anywhere near the brewing process either.

measuring SG with an ATC Brix Refractometer

Boil Kettle. Notice the missing butterfly nut on the bottom plate. Stepehen got it just in time, but maybe wasn’t quite tight enough which caused the blockage later in the pump.

clearing the blockage in the pump - maybe hop leaf got into the Boil Kettle

Yeast: WHC Lab Saturated 18-22 degrees

Very dark, and we ended up adding treated water to give us 1062 at about 80 litres

Ferment

Left in a garage for 2 weeks so between 13 and 16 degrees. Probably not ideal. 22nd Oct 2022

Notice no airlock, and have cracked the lid too.

FG was: 1023 - I think it is still fermenting. So am leaving another week at 18 degrees to see if it will finish. Smells and tasted really good.

Bottle

28th Oct 2022, FG was 1016 which is expected. So it took just under 3 weeks to ferment to FG.

Tasted the beer and it was lovely

https://www.hopsteiner.com/co2-calculator/ - 2.6 CO2 - need 65g of sucrose

I’ve got 1 plastic bottle so can tell how much CO2 is there by squeezing it.

4 Weeks conditioning

It tastes much better than a few weeks ago - properly good!